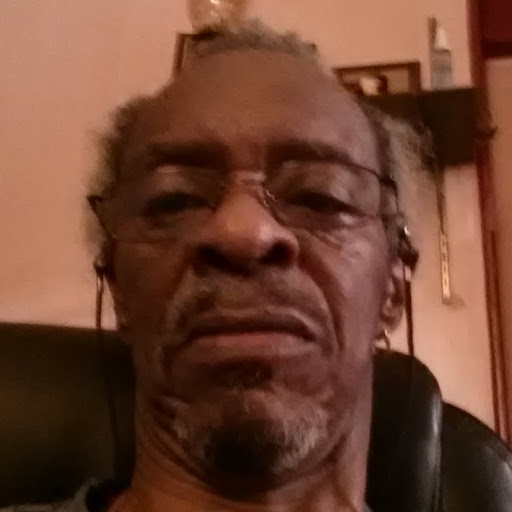

Frederick M Walker

age ~93

from Cherry Hill, NJ

- Also known as:

-

- Frederick F Walker

- Frederick E Walker

- Frederick L Walker

- Fred M Walker

- Fred E Walker

- Fred L Walker

- Frederic M Walker

- Fredrick L Walker

- Frank Walker

- Phone and address:

-

48 Oakview Ave, Cherry Hill, NJ 08002

856 662-1370

Frederick Walker Phones & Addresses

- 48 Oakview Ave, Cherry Hill, NJ 08002 • 856 662-1370

- Waretown, NJ

- Havertown, PA

- Wrightstown, NJ

- Robbinsville, NJ

- Goodwine, IL

- Annandale, VA

- Havertown, PA

- 48 Oakview Ave, Cherry Hill, NJ 08002 • 856 297-9366

Work

-

Company:Pavilion of forestall villageNov 2013

-

Position:Dietary aide

Education

-

School / High School:Trenton Central High SchoolSep 1994

-

Specialities:diploma in general

Medicine Doctors

Frederick A. Walker

view sourceSpecialties:

Psychiatry

Work:

Creative Psychiatry PLLC

10200 Frst Grn Blvd STE 401, Louisville, KY 40223

502 384-2343 (phone), 502 365-2937 (fax)

10200 Frst Grn Blvd STE 401, Louisville, KY 40223

502 384-2343 (phone), 502 365-2937 (fax)

Education:

Medical School

A.T. Still University of Health Sciences/ Kirksville College of Osteopathic Medicine

Graduated: 2001

A.T. Still University of Health Sciences/ Kirksville College of Osteopathic Medicine

Graduated: 2001

Conditions:

Anxiety Phobic Disorders

Attention Deficit Disorder (ADD)

Depressive Disorders

Attention Deficit Disorder (ADD)

Depressive Disorders

Languages:

English

Description:

Dr. Walker graduated from the A.T. Still University of Health Sciences/ Kirksville College of Osteopathic Medicine in 2001. He works in Louisville, KY and specializes in Psychiatry.

Frederick Douglas Walker

view sourceSpecialties:

Anatomic Pathology & Clinical Pathology

Blood Banking & Transfusion Medicine

Blood Banking & Transfusion Medicine

Education:

Loyola University Chicago (1974)

Wikipedia References

Frederick Walker

About:

Died:

1866

Work:

Position:

Property Manager

Skills & Activities:

Area of science:

Explorer of Australia

Name / Title

Company / Classification

Phones & Addresses

Manager

Meds Primary Data Source, LLC

JR AND CC, LLC

Resumes

Frederick Walker

view source

Order Picker

view sourceWork:

Order Picker

Frederick Allen Walker

view sourceSkills:

Forrester

Frederick Walker

view source

Performing Artist

view sourceWork:

Performing Artist

Frederick Walker Trenton, NJ

view sourceWork:

Pavilion of Forestall Village

Nov 2013 to 2000

Dietary Aide Burlington Coat Factory

East Windsor, NJ

Oct 2012 to Feb 2013

Stock Associate Recieving Customer Service Prologistix of Kenco

Robbinsville, NJ

Aug 2012 to Oct 2012

Picker and Packer Family Dollar

Ewing, NJ

Jun 2012 to Aug 2012

Cashier/Customer Service Allied Concrete and Construction

Jan 2008 to Jul 2008

Laborer Aramark of Harrison Lodging

Plainsboro, NJ

Oct 2006 to Jan 2007

Housekeeping Friends Deli

Trenton, NJ

Utility Worker, prep cook

Nov 2013 to 2000

Dietary Aide Burlington Coat Factory

East Windsor, NJ

Oct 2012 to Feb 2013

Stock Associate Recieving Customer Service Prologistix of Kenco

Robbinsville, NJ

Aug 2012 to Oct 2012

Picker and Packer Family Dollar

Ewing, NJ

Jun 2012 to Aug 2012

Cashier/Customer Service Allied Concrete and Construction

Jan 2008 to Jul 2008

Laborer Aramark of Harrison Lodging

Plainsboro, NJ

Oct 2006 to Jan 2007

Housekeeping Friends Deli

Trenton, NJ

Utility Worker, prep cook

Education:

Trenton Central High School

Sep 1994 to Jun 1998

diploma in general

Sep 1994 to Jun 1998

diploma in general

Us Patents

-

Primary-Tertiary Diamines Mixed With Polyamines As Epoxy Resin Hardeners

view source -

US Patent:56889054, Nov 18, 1997

-

Filed:Sep 20, 1995

-

Appl. No.:8/530813

-

Inventors:Frederick Herbert Walker - Doylestown PA

-

Assignee:Air Products and Chemicals, Inc. - Allentown PA

-

International Classification:C08G 6934

C08L 6302

C08L 6304 -

US Classification:528332

-

Abstract:An amine hardener composition for curing epoxy resin based coatings and related products comprising (A) from 5 to 75% of a diamine which possesses a vapor pressure less than about 133 Pascals at 20. degree. C. , contains both a primary and a tertiary amine and corresponds to either of the structures: ##STR1## where R. sub. 1 and R. sub. 2 are independently C. sub. 1 -C. sub. 8 alkyl; X is --CH. sub. 2 --CH. sub. 2 --, --CH. sub. 2 --CH. sub. 2 --CH. sub. 2 --, or --CH. sub. 2 --O--CH. sub. 2 --; and n is 2-6, (B) from 5 to 95% of a polyamide, amidoamine, Mannich base or cycloaliphatic amine curing agent; and (C) from 0 to 50% of other active hydrogen containing dismines or polyamines. Coatings based on the composition can be formulated at up to 100% solids, and have an excellent combination of pot life and dry speed.

-

Amide-Containing Self-Emulsifying Epoxy Curing Agent

view source -

US Patent:55764169, Nov 19, 1996

-

Filed:Dec 13, 1994

-

Appl. No.:8/355149

-

Inventors:Frederick H. Walker - Doylestown PA

-

Assignee:Air Products and Chemicals, Inc. - Allentown PA

-

International Classification:C08G 6926

-

US Classification:528340

-

Abstract:A new epoxy hardener composition is the product of the reaction of (A) a poly(alkylene oxide) monoamine or diamine with a molecular weight (Mn) of about 500 to 3000 and (B) a di- or polycarboxylic acid, in a ratio of moles of carboxylic acid to equivalents of amine of about 1:1 to 6:1 to yield an intermediate (C), which in a second step is reacted with (D) a di- or polyamine. The compositions of the invention are excellent emulsifiers of liquid epoxy resins in aqueous media without the addition of added surfactants or acidic compounds, and can be used to prepare water resistant water-borne coatings and related products from both liquid and solid epoxy resins, that possess long pot lives and contain relatively small amounts of volatile organic compounds.

-

Self-Emulsifying Epoxy Curing Agent

view source -

US Patent:55998550, Feb 4, 1997

-

Filed:Jun 5, 1995

-

Appl. No.:8/463477

-

Inventors:Frederick H. Walker - Doylestown PA

-

Assignee:Air Products and Chemicals, Inc. - Allentown PA

-

International Classification:C08K 320

C08L 6302

C08L 6304 -

US Classification:523404

-

Abstract:A new epoxy hardener composition is the product of the reaction of (A) a poly(alkylene oxide) monoamine or diamine with a molecular weight (Mn) of about 500 to 6000 and (B) a di- or polyepoxide, in a ratio of epoxide to active amine hydrogens of about 1. 1:1 to 6:1 to yield an intermediate (C), which in a second step is reacted with (D) a di- or polyamine, in a ratio of active amine hydrogens to epoxide of greater than about 25 to 1, preferably greater than about 30 to 1. The compositions of the invention are excellent emulsifiers of liquid epoxy resins in aqueous medium without the addition of added surfactants or acidic compounds, and can be used to prepare water resistant water-borne coatings and related products from both liquid and solid epoxy resins, that possess long pot lives and contain relatively small amounts of volatile organic compounds.

-

Self-Emulsifying Epoxy Curing Agent

view source -

US Patent:54896304, Feb 6, 1996

-

Filed:Nov 28, 1994

-

Appl. No.:8/345164

-

Inventors:Frederick H. Walker - Doylestown PA

-

Assignee:Air Products and Chemicals, Inc. - Allentown PA

-

International Classification:C08K 320

C08L 6302

C08L 6304 -

US Classification:523404

-

Abstract:A new epoxy hardener composition is the product of the reaction of (A) a poly(alkylene oxide) monoamine or diamine with a molecular weight (Mn) of about 500 to 3000 and (B) a di- or polyepoxide, in a ratio of epoxide to active amine hydrogens of about 1. 1:1 to 6:1 to yield an intermediate (C), which in a second step is reacted with (D) a di- or polyamine, in a ratio of active amine hydrogens to epoxide of greater than about 25 to 1, preferably greater than about 30 to 1. The compositions of the invention are excellent emulsifiers of liquid epoxy resins in aqueous medium without the addition of added surfactants or acidic compounds, and can be used to prepare water resistant water-borne coatings and related products from both liquid and solid epoxy resins, that possess long pot lives and contain relatively small amounts of volatile organic compounds.

-

Non-Aqueous Dispersion For Alkyd Formulation

view source -

US Patent:54911923, Feb 13, 1996

-

Filed:Aug 28, 1991

-

Appl. No.:7/754262

-

Inventors:Frederick H. Walker - Hatfield PA

Chao-Jen Chung - Gwynedd PA

Andrew Mercurio - Gwynedd Valley PA -

Assignee:Rohm and Haas Company - Philadelphia PA

-

International Classification:C08L 6708

-

US Classification:525 74

-

Abstract:A non-aqueous dispersion for modifying alkyd-containing coating formulations and a method for manufacturing the non-aqueous dispersion are provided. The non-aqueous dispersion contains from about 10 to about 60 parts by weight of a low molecular weight solution polymer, having a selected glass transition temperature greater than about -10. degree. C. , and from about 90 to about 40 parts by weight of a polymer which is insoluble in the non-aqueous medium, and where the soluble polymer is attached to or adsorbed onto the insoluble polymer particles. The non-aqueous dispersion is preferably prepared by dispersion polymerization to form the insoluble polymer in a non-aqueous medium in the presence of the soluble polymer.

-

Amide-Containing Self-Emulsifying Epoxy Curing Agent

view source -

US Patent:55960308, Jan 21, 1997

-

Filed:Oct 3, 1995

-

Appl. No.:8/538671

-

Inventors:Frederick H. Walker - Doylestown PA

-

Assignee:Air Products and Chemicals, Inc. - Allentown PA

-

International Classification:C08K 320

C08L 6302 -

US Classification:523404

-

Abstract:A new epoxy hardener composition is the product of the reaction of (A) a poly(alkylene oxide) monoamine or diamine with a molecular weight (Mn) of about 500 to 3000 and (B) a di- or polycarboxylic acid, in a ratio of moles of carboxylic acid to equivalents of amine of about 1:1 to 6:1 to yield an intermediate (C), which in a second step is reacted with (D) a di- or polyamine. The compositions of the invention are excellent emulsifiers of liquid epoxy resins in aqueous media without the addition of added surfactants or acidic compounds, and can be used to prepare water resistant water-borne coatings and related products from both liquid and solid epoxy resins, that possess long pot lives and contain relatively small amounts of volatile organic compounds.

-

Self-Emulsifying Epoxy Curing Agent Based On The Reaction Product Of Epoxy Resin And Polyether Polyol

view source -

US Patent:55278396, Jun 18, 1996

-

Filed:Dec 13, 1994

-

Appl. No.:8/355150

-

Inventors:Frederick H. Walker - Doylestown PA

-

Assignee:Air Products and Chemicals, Inc. - Allentown PA

-

International Classification:C08K 320

C08L 6302

C08L 6304 -

US Classification:523404

-

Abstract:A new epoxy hardener composition is the product of the reaction of (A) a poly(alkylene oxide) monoalcohol with a molecular weight (Mn) of about 500 to 3000 and (B) a polyepoxide, in a molar ratio of polyepoxide to poly(alkylene oxide) monoalcohol of about 1. 3:1 to 6:1 to yield an intermediate (C), which in a second step is reacted with (D) a polyamine. The compositions of the invention are excellent emulsifiers of liquid epoxy resins in aqueous media without the addition of added surfactants or acidic compounds, and can be used to prepare water resistant water-borne coatings and related products from both liquid and solid epoxy resins, that possess long pot lives and contain relatively small amounts of volatile organic compounds.

Myspace

Classmates

Frederick Wickenheiser (W...

view sourceSchools:

St. Patrick School Carleton MI 1961-1965

Community:

Dana Rose, Sharon Bost, Ernest Morse

Frederick Keith Walker

view sourceSchools:

Nelson County High School Lovingston VA 1986-1990

Community:

Coyt Shirley, Rebecca Clayton, Melissa Fortune, Lorna Ballowe

Frederick Walker

view sourceSchools:

Wendell Wilkie Middle School Elwood IN 1944-1948, Wendell L. Willkie High School Elwood IN 1950-1952

Community:

Robert W

Frederick Walker

view sourceSchools:

Northside Christian High School North Charleston SC 1989-1992

Community:

Stephanie Tanner, Nichole Argus, Reece Flynt

Frederick Walker

view sourceSchools:

Carver High School New Orleans LA 1971-1975

Community:

Kelvin Lee, Dionnka Posey, Patricia Saulny, Shuntel Morris

Frederick Walker

view sourceSchools:

Mount Vernon Junior High School Los Angeles CA 1974-1977

Community:

Sheila Whitney, Robert Estell, Michelle Garrett, Charmagne Wilson

Frederick Walker

view sourceSchools:

Concord High School Concord MA 1951-1955

Community:

Judi Arnott, Dale Gunn, Wallace Crawford

Frederick Walker

view sourceSchools:

Grove Park Elementary School Atlanta GA 1962-1969

Community:

Jacqueline Snead, Mary Bart, Stanley Abercrombie

Googleplus

Frederick Walker

Frederick Walker

Frederick Walker

Frederick Walker

Tagline:

Inspiring Entrepneur,Real Estate Investor,Visionary,Leader,Fath... of 1

Frederick Walker

Frederick Walker

Frederick Walker

Frederick Walker

Frederick Walker

view source

Frederick Walker

view source

Frederick Walker

view source

Frederick Walker

view source

Frederick A. Walker

view source

Frederick G. Walker

view source

Frederick Allen Walker

view source

Frederick Elliott Walker

view sourceFlickr

Youtube

Get Report for Frederick M Walker from Cherry Hill, NJ, age ~93