Matthew Robert King

age ~48

from Wilmington, DE

- Also known as:

-

- Matthew R King

- Matthew A King

- Matthew M King

- Matt A King

- Matt R King

- Phone and address:

- 1641 Coleman St, Wilmington, DE 19805

Matthew King Phones & Addresses

- 1641 Coleman St, Wilmington, DE 19805

- Birmingham, AL

- Newark, DE

- Montgomeryville, PA

- Montgomery, AL

Isbn (Books And Publications)

-

Partners In Progresss: Strengthening The Superintendent-Board Relationship

view source -

Author:Matthew King

-

ISBN #:0787948659

-

Trends In The Health Of Canadian Youth

view source -

Author:Matthew A. King

-

ISBN #:0662279514

-

Sulphuric Acid Manufacture: Analysis, Control And Optimization

view source -

Author:Matthew J. King

-

ISBN #:0080444288

Lawyers & Attorneys

Matthew King - Lawyer

view sourceSpecialties:

Taxation

ISLN:

910307008

Admitted:

1995

University:

University of St. Thomas, B.A., 1992

Law School:

William Mitchell College of Law, J.D., 1995

Matthew King - Lawyer

view sourceISLN:

918412469

Admitted:

2004

University:

Colby College, B.A., 1998

Law School:

College of William & Mary, J.D., 2004

Matthew King - Lawyer

view sourceSpecialties:

Business

Securities & Investment Fraud

Securities & Investment Fraud

ISLN:

1000765250

Admitted:

2016

Matthew King - Lawyer

view sourceOffice:

Ozark Sash & Door, Inc.

Specialties:

Real Estate Law

Contract Law

General Practice

Contract Law

General Practice

ISLN:

912473688

Admitted:

1996

University:

University of Arkansas at Fayetteville, B.A., 1992

Law School:

University of Arkansas at Fayetteville, J.D., 1996

Matthew King - Lawyer

view sourceSpecialties:

Bankruptcy

Corporate Reorganization

Corporate

Litigation

Corporate Reorganization

Corporate

Litigation

ISLN:

905875178

Admitted:

1987

University:

State University of New York at Stony Brook, B.A., 1983

Law School:

Case Western Reserve University, J.D., 1986

Matthew King - Lawyer

view sourceOffice:

Milne Selkirk

Specialties:

General Practice

ISLN:

905875130

Admitted:

1985

University:

University of British Columbia, 1979

Law School:

University of Victoria, LL.B., 1984

Matthew King - Lawyer

view sourceOffice:

Frost Brown Todd LLC

Specialties:

Products Liability

Litigation Section

Litigation Section

ISLN:

917410893

Admitted:

2003

University:

College of Wooster, B.A., 2000; College of Wooster, B.A., 2000

Law School:

Indiana University School of Law, J.D., 2003

Matthew King - Lawyer

view sourceSpecialties:

Licensing

Advertising

Intellectual Property

Advertising

Advertising

Intellectual Property

Advertising

ISLN:

1000601566

Admitted:

2008

License Records

Matthew Lloyd King

License #:

CPA.0027169 - Expired

Category:

Certified Public Accountant

Expiration Date:

Dec 31, 2016

Matthew T King

License #:

1814 - Expired

Category:

Emergency Medical Care

Issued Date:

Apr 15, 2003

Effective Date:

Feb 5, 2007

Expiration Date:

Dec 31, 2006

Type:

First Responder

Matthew B King

License #:

2897 - Expired

Category:

Water Operator

Issued Date:

May 16, 2011

Effective Date:

Jan 10, 2014

Expiration Date:

Dec 31, 2013

Type:

Grade III Water Operator

Matthew King

License #:

35969 - Active

Category:

Professional

Issued Date:

Jan 25, 2001

Expiration Date:

Mar 31, 2019

Us Patents

-

Ovjp System And Sublimation Source

view source -

US Patent:20220352467, Nov 3, 2022

-

Filed:Apr 26, 2022

-

Appl. No.:17/729465

-

Inventors:- Ewing NJ, US

Craig Anthony OUTTEN - Rydal PA, US

Gregory MCGRAW - Yardley PA, US

Matthew KING - Moorestown NJ, US

Xin XU - Plainsboro NJ, US -

International Classification:H01L 51/00

C23C 14/12

C23C 14/22

C23C 16/44 -

Abstract:Organic vapor jet printing (OVJP) devices and techniques are provided that use a solid materials sublimation source to provide material for deposition on a substrate. Carrier gas from a carrier gas source entrains vapor from the solid material within each sublimation source for transport to a print head within a deposition chamber. The sublimation source includes a sufficiently long internal flow path to achieve an acceptable level of material saturation of the carrier gas.

-

Printed Metal Gasket

view source -

US Patent:20210367217, Nov 25, 2021

-

Filed:Aug 5, 2021

-

Appl. No.:17/394769

-

Inventors:- Ewing NJ, US

Jason PAYNTER - Bristol PA, US

Gregory MCGRAW - Yardley PA, US

Matthew KING - Moorestown NJ, US -

International Classification:H01L 51/56

H01L 51/52

H01L 51/00 -

Abstract:Techniques and devices are provided for attaching a die to a metal manifold. A metal-containing ink is used to deposit a metal trace on the die and thereby to form a gasket, after which the die is compressed against the manifold to form a sealed connection between the two.

-

Modular Confined Organic Print Head And System

view source -

US Patent:20210355575, Nov 18, 2021

-

Filed:Jul 30, 2021

-

Appl. No.:17/389694

-

Inventors:- Ewing NJ, US

Gregory MCGRAW - Yardley PA, US

Matthew KING - Moorestown NJ, US

Gregg KOTTAS - Ewing NJ, US -

International Classification:C23C 14/22

C23C 14/12

C23C 14/24 -

Abstract:Embodiments of the disclosed subject matter provide a vapor distribution manifold that ejects organic vapor laden gas into a chamber and withdraws chamber gas, where vapor ejected from the manifold is incident on, and condenses onto, a deposition surface within the chamber that moves relative to one or more print heads in a direction orthogonal to a platen normal and a linear extent of the manifold. The volumetric flow of gas withdrawn by the manifold from the chamber may be greater than the volumetric flow of gas injected into the chamber by the manifold. The net outflow of gas from the chamber through the manifold may prevent organic vapor from diffusing beyond the extent of the gap between the manifold and deposition surface. The manifold may be configured so that long axes of delivery and exhaust apertures are perpendicular to a print direction.

-

Modular Confined Organic Print Head And System

view source -

US Patent:20190256968, Aug 22, 2019

-

Filed:Jan 23, 2019

-

Appl. No.:16/255040

-

Inventors:- Ewing NJ, US

Gregory MCGRAW - Yardley PA, US

Matthew KING - Moorestown NJ, US

Gregg KOTTAS - Ewing NJ, US -

International Classification:C23C 14/22

C23C 14/12

C23C 14/24 -

Abstract:Embodiments of the disclosed subject matter provide a vapor distribution manifold that ejects organic vapor laden gas into a chamber and withdraws chamber gas, where vapor ejected from the manifold is incident on, and condenses onto, a deposition surface within the chamber that moves relative to one or more print heads in a direction orthogonal to a platen normal and a linear extent of the manifold. The volumetric flow of gas withdrawn by the manifold from the chamber may be greater than the volumetric flow of gas injected into the chamber by the manifold. The net outflow of gas from the chamber through the manifold may prevent organic vapor from diffusing beyond the extent of the gap between the manifold and deposition surface. The manifold may be configured so that long axes of delivery and exhaust apertures are perpendicular to a print direction.

-

Valved Micronozzle Array For High Temperature Mems Application

view source -

US Patent:20190217610, Jul 18, 2019

-

Filed:Jan 9, 2019

-

Appl. No.:16/243393

-

Inventors:- Ewing NJ, US

Matthew KING - Evesham NJ, US

William E. QUINN - Whitehouse Station NJ, US -

International Classification:B41J 2/14

B05B 1/16

B41J 2/16 -

Abstract:Embodiments of the disclosed subject matter provide a micronozzle array formed from monolithic silicon. The micronozzle array may have a plurality of nozzles, where each nozzle of the plurality of nozzles including an integrated plug valve that allows flow from the nozzle to be attenuated separately from each other nozzle of the plurality of nozzles. Each of the plurality of nozzles may include a microchannel, formed from the monolithic silicon, having a first channel portion and a second channel portion, where the first channel portion is narrower than the second channel portion, and where the first channel portion forms an aperture of the nozzle that is configured to eject vapor from the microchannel. Each of the plurality of nozzles may include a stem, formed from the monolithic silicon that includes the integrated plug valve is suspended in the microchannel to attenuate the flow from the nozzle.

-

Printed Metal Gasket

view source -

US Patent:20190214603, Jul 11, 2019

-

Filed:Jan 11, 2019

-

Appl. No.:16/245517

-

Inventors:- Ewing NJ, US

Jason PAYNTER - Bristol PA, US

Gregory MCGRAW - Yardley PA, US

Matthew KING - Evesham NJ, US -

International Classification:H01L 51/56

H01L 51/52

H01L 51/00 -

Abstract:Techniques and devices are provided for attaching a die to a metal manifold. A metal-containing ink is used to deposit a metal trace on the die and thereby to form a gasket, after which the die is compressed against the manifold to form a sealed connection between the two.

-

Nozzle Assembly And Nozzle Array For Ovjp

view source -

US Patent:20180331327, Nov 15, 2018

-

Filed:Feb 24, 2017

-

Appl. No.:15/441331

-

Inventors:- Ewing NJ, US

Gregory McGRAW - Yardley PA, US

Siddharth HARIKRISHNA MOHAN - Plainsboro NJ, US

Matthew KING - Evesham NJ, US -

International Classification:H01L 51/56

B05B 15/02

C23C 14/12

C23C 14/22 -

Abstract:Embodiments of the disclosed subject matter provide a nozzle assembly and method of making the same, the nozzle assembly including a first aperture formed on a first aperture plate to eject a carrier gas flow having organic vapor onto a substrate in a deposition chamber, second apertures formed on a second aperture plate disposed adjacent to the first aperture to form a vacuum aperture, where the first aperture plate and the second aperture plate are separated by a first separator plate, third apertures formed on a third aperture plate to eject purge gas that are disposed adjacent to the second aperture plate, where the second aperture plate and the third aperture plate are separated by second separator plate, and a third separator plate is disposed adjacent to the one or more third aperture plates to form a gas channel in the one or more third aperture plates.

-

Micro-Nozzle And Micro-Nozzle Array For Ovjp And Method Of Manufacturing The Same

view source -

US Patent:20160083845, Mar 24, 2016

-

Filed:Sep 18, 2015

-

Appl. No.:14/858840

-

Inventors:- Ewing NJ, US

Gregory McGRAW - Yardley PA, US

Siddharth HARIKRISHNA MOHAN - Plainsboro NJ, US

Matthew KING - Evesham NJ, US -

International Classification:C23C 16/455

H01L 51/50

B05B 15/04

B05B 1/00

B05B 1/28

B05B 1/14

C23C 14/22

H01L 51/56 -

Abstract:Embodiments of the disclosed subject matter provide a nozzle assembly and method of making the same, the nozzle assembly including a first aperture formed on a first aperture plate to eject a carrier gas flow having organic vapor onto a substrate in a deposition chamber, second apertures formed on a second aperture plate disposed adjacent to the first aperture to form a vacuum aperture, where the first aperture plate and the second aperture plate are separated by a first separator plate, third apertures formed on a third aperture plate to eject purge gas that are disposed adjacent to the second aperture plate, where the second aperture plate and the third aperture plate are separated by second separator plate, and a third separator plate is disposed adjacent to the one or more third aperture plates to form a gas channel in the one or more third aperture plates.

Resumes

Matthew King Prattville, AL

view sourceWork:

WIND CREEK CASINO

Oct 2013 to 2000

BEVERAGE SUPERVISOR FASTENAL

Prattville, AL

May 2011 to Sep 2013

GENERAL MANAGER O'CHARLEY'S

Prattville, AL

Apr 2004 to May 2011

BAR MANAGER

Oct 2013 to 2000

BEVERAGE SUPERVISOR FASTENAL

Prattville, AL

May 2011 to Sep 2013

GENERAL MANAGER O'CHARLEY'S

Prattville, AL

Apr 2004 to May 2011

BAR MANAGER

Education:

AUBURN UNIVERSITY OF MONTGOMERY

Montgomery, AL

2002 to 2004

Business STANHOPE ELMORE HIGH SCHOOL

Millbrook, AL

1998 to 2002

Diploma

Montgomery, AL

2002 to 2004

Business STANHOPE ELMORE HIGH SCHOOL

Millbrook, AL

1998 to 2002

Diploma

Matthew King Willingboro, NJ

view sourceWork:

Communities in Schools of Philadelphia

Aug 2010 to 2000

PROGRAM COORDINATOR School District of Philadelphia

Philadelphia, PA

Mar 2009 to Aug 2010

PROJECT MANAGER (INTERNSHIP)

Aug 2010 to 2000

PROGRAM COORDINATOR School District of Philadelphia

Philadelphia, PA

Mar 2009 to Aug 2010

PROJECT MANAGER (INTERNSHIP)

Education:

DeVry University

Fort Washington, PA

2006 to 2010

BSBA Business Administration in Project Management

Fort Washington, PA

2006 to 2010

BSBA Business Administration in Project Management

Matthew King Marlton, NJ

view sourceWork:

Aries Filterworks

Apr 2013 to 2000

Product Development Engineer VEECO CORPORATION

Somerset, NJ

2007 to 2012

Hardware Development Engineer RANDOLPH BOARD OF EDUCATION, Randolph, NJ

New York, NY

2005 to 2007

High School Mathematics Teacher SHUBHADA INDUSTRIES

Mount Laurel, NJ

2004 to 2005

Junior Mechanical Engineer

Apr 2013 to 2000

Product Development Engineer VEECO CORPORATION

Somerset, NJ

2007 to 2012

Hardware Development Engineer RANDOLPH BOARD OF EDUCATION, Randolph, NJ

New York, NY

2005 to 2007

High School Mathematics Teacher SHUBHADA INDUSTRIES

Mount Laurel, NJ

2004 to 2005

Junior Mechanical Engineer

Education:

Stevens Institute of Technology

Hoboken, NJ

2010

Master of Science in Mechanical Engineering Rowan University

Glassboro, NJ

2005

Graduate Certificate

Hoboken, NJ

2010

Master of Science in Mechanical Engineering Rowan University

Glassboro, NJ

2005

Graduate Certificate

Matthew King

view source

Matthew King

view sourceMedicine Doctors

Matthew King

view sourceSpecialties:

Family Medicine

Work:

Reiter Hill Johnson & Nevin Mds

1145 19 St NW STE 410, Washington, DC 20036

202 331-1740 (phone), 202 296-9784 (fax)

Reiter Hill Johnson & Nevin Mds

5550 Friendship Blvd STE 210, Chevy Chase, MD 20815

301 654-5700 (phone), 301 718-8330 (fax)

Reiter Hill Johnson & Nevin Mds

407 N Washington St STE 105, Falls Church, VA 22046

703 533-9211 (phone), 703 533-9401 (fax)

Anne Arundel Medical GroupEastern Shore Primary Care

1630 Main St STE 204, Chester, MD 21619

410 643-4524 (phone), 410 643-4523 (fax)

1145 19 St NW STE 410, Washington, DC 20036

202 331-1740 (phone), 202 296-9784 (fax)

Reiter Hill Johnson & Nevin Mds

5550 Friendship Blvd STE 210, Chevy Chase, MD 20815

301 654-5700 (phone), 301 718-8330 (fax)

Reiter Hill Johnson & Nevin Mds

407 N Washington St STE 105, Falls Church, VA 22046

703 533-9211 (phone), 703 533-9401 (fax)

Anne Arundel Medical GroupEastern Shore Primary Care

1630 Main St STE 204, Chester, MD 21619

410 643-4524 (phone), 410 643-4523 (fax)

Education:

Medical School

University of Maryland School of Medicine

Graduated: 2003

University of Maryland School of Medicine

Graduated: 2003

Procedures:

Allergen Immunotherapy

Arthrocentesis

Destruction of Benign/Premalignant Skin Lesions

Electrocardiogram (EKG or ECG)

Hearing Evaluation

Skin Tags Removal

Vaccine Administration

Arthrocentesis

Destruction of Benign/Premalignant Skin Lesions

Electrocardiogram (EKG or ECG)

Hearing Evaluation

Skin Tags Removal

Vaccine Administration

Conditions:

Abdominal Hernia

Abnormal Vaginal Bleeding

Acne

Acute Bronchitis

Acute Pharyngitis

Abnormal Vaginal Bleeding

Acne

Acute Bronchitis

Acute Pharyngitis

Languages:

English

Description:

Dr. King graduated from the University of Maryland School of Medicine in 2003. He works in Falls Church, VA and 3 other locations and specializes in Family Medicine. Dr. King is affiliated with Anne Arundel Medical Center and Sibley Memorial Hospital.

Matthew J. King

view sourceSpecialties:

Internal Medicine

Work:

Byrdstown Medical Center

8401 Hwy 1 11, Byrdstown, TN 38549

931 864-3187 (phone), 931 864-7102 (fax)

8401 Hwy 1 11, Byrdstown, TN 38549

931 864-3187 (phone), 931 864-7102 (fax)

Education:

Medical School

University of Tennessee College of Medicine at Memphis

Graduated: 1996

University of Tennessee College of Medicine at Memphis

Graduated: 1996

Languages:

English

Description:

Dr. King graduated from the University of Tennessee College of Medicine at Memphis in 1996. He works in Byrdstown, TN and specializes in Internal Medicine. Dr. King is affiliated with Livingston Regional Hospital.

Matthew King

view sourceSpecialties:

Orthopaedic Surgery

Work:

Next Step Orthopedics

8865 Synergy Dr STE 101, McKinney, TX 75070

866 495-9204 (phone), 972 547-0065 (fax)

8865 Synergy Dr STE 101, McKinney, TX 75070

866 495-9204 (phone), 972 547-0065 (fax)

Languages:

English

Description:

Mr. King works in McKinney, TX and specializes in Orthopaedic Surgery. Mr. King is affiliated with Medical Center Of Mckinney.

Matthew Joel King

view sourceSpecialties:

Internal Medicine

Pulmonary Disease

Pediatrics

Hospitalist

Pulmonary Disease

Pediatrics

Hospitalist

Education:

University of Tennessee (1996)

Matthew Sidney King

view sourceSpecialties:

Internal Medicine

Critical Care Medicine

Pulmonary Disease

Hospitalist

Critical Care Medicine

Pulmonary Disease

Hospitalist

Education:

Indiana University(2004)

Matthew James King

view sourceName / Title

Company / Classification

Phones & Addresses

Managing

Matt King Consulting LLC

Manager

Matthew King's Victory Gardens, LLC

Design/construct Raised-Bed Garden Concepts

Design/construct Raised-Bed Garden Concepts

Birmingham, AL 35244

incorporator

Hands On Development Inc

DEVELOPMENT/MARKETING/SALE OF COMPUTER SOFTWARE

DEVELOPMENT/MARKETING/SALE OF COMPUTER SOFTWARE

Montgomery, AL

Creatasoft, LLC

General Opertation Of Computer Software Development

General Opertation Of Computer Software Development

Montgomery, AL

GET UR TAN ON LLC

DYNAMIC CONSTRUCTION SPECIALTIES, INC

BEREA CUSTOM CORNHOLE, LLC

EXCEL SPORTS CONSULTANTS, LTD

Flickr

Classmates

Matthew King

view sourceSchools:

Pepperell Middle School Lindale GA 2000-2004

Community:

Tracy Lawler, Leslie Adams

Matthew King

view sourceSchools:

Warwick High School Newport News VA 2003-2007

Community:

Collin Long, Ronald Fox

Matthew King

view sourceSchools:

Delta Academy Marks MS 2002-2006

Community:

Les Hooper, Dale Barnes, Lee Mckee, Gary Shepherd

Matthew King

view sourceSchools:

Southwest Academy Jackson MS 2000-2004

Matthew King

view sourceSchools:

Elmendorf Air Force Base Elementary School Anchorage AK 1959-1962

Community:

Brenda Riddle, Connie Keehn

Matthew King

view sourceSchools:

Longan Elementary School Richmond VA 1972-1978, Tuckahoe Middle School Richmond VA 1978-1980

Community:

Ann Clemmons, Michelle Baughman, Joyce Kondik

Matthew King

view sourceSchools:

Bethesda Christian High School Brownsburg IN 1996-2002

Community:

Julie Takach, Leslie Knox, Brad Taylor, Shari Blanton

Matthew King

view sourceSchools:

Rural Retreat High School Rural Retreat VA 2002-2006

Community:

Betty Walk, Thomas Stone

Matthew Calypso King

view source

Matthew Sebastian King

view source

Matthew Stephen King

view source

Jesse Matthew King

view source

Matthew King

view source

James Matthew King

view source

Matthew Christian King

view source

Matthew King Mufasa

view sourceGoogleplus

Matthew King

Work:

New Brockton Fire Dept. - Training Capt. (2010)

Fort Rucker Fire Dept. - Firefighter (2011)

US Army - Sgt (2002-2011)

Flatiron - Crash Rescue (2010-2011)

Fort Rucker Fire Dept. - Firefighter (2011)

US Army - Sgt (2002-2011)

Flatiron - Crash Rescue (2010-2011)

Education:

Poolesville High School

Matthew King

Work:

KSM Consulting (A Katz, Sapper & Miller Co.) - ERP Practice Lead (2011)

Sikich - Sr. Consultant (2006-2011)

EDI Consulting Group - Operations Manager (2003-2006)

Sikich - Sr. Consultant (2006-2011)

EDI Consulting Group - Operations Manager (2003-2006)

Education:

Kelley School of Business - Accounting

Relationship:

Married

Matthew King

Work:

Telstra - BigPond Money - Finance Manager (2011)

Education:

University of Sydney - History/Politics, Knox Grammar

About:

I see myself as web evangelist and I pride myself in having a user focused, broad technology understanding with a keen interest in the convergence of the digital world and day to day experien...

Bragging Rights:

Professional Specialties: Web strategy and development for high volume sites, digital publishing, online advertising and marketing, social networking, project & team management, Information Architecture and User Interface design, Systems Specification and Business Analysis, e-commerce (full cycle), web based content management, authoring and design and SEO/SEM.

Matthew King

Work:

Harvey Norman - TV MAN (2009)

Education:

Some School

Tagline:

SUP

Matthew King

Education:

Eastern Nazarene College - Electrical Engineering

Relationship:

Married

Tagline:

Proud Father and a Rockin' Drummer

Bragging Rights:

I'm an engineer, I've rocked the skins in several bands, and have a great family with one padawan runnin' around and one on the way.

Matthew King

Work:

King Law Offices - Attorney (2007)

Education:

DePaul University College of Law

Matthew King

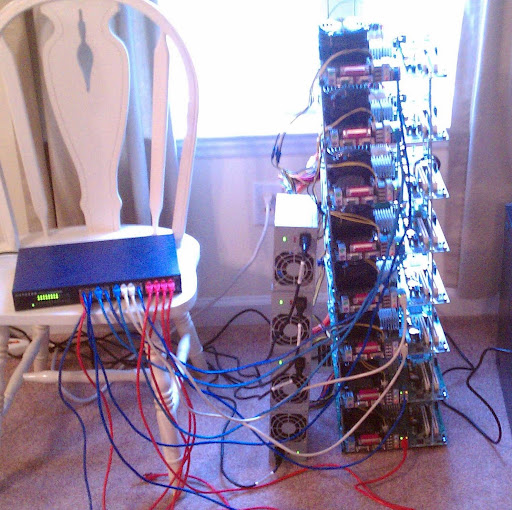

Education:

Duke University - ECE, Purdue University - ECET

About:

Lover of all things Google, Computer Engineer, software developer, hardware designer.

Bragging Rights:

Have my own 16 node cluster in my guestroom :)

Matthew King

Education:

United States Merchant Marine Academy - Marine Engineering / Nautical Science, Yuma High School, Apple Valley High School

Plaxo

Matthew King

view sourceJP Morgan

Matthew King

view sourceCincinnati, Ohio

Matthew King

view sourceEMeRged Healthcare Solutions

Matthew King

view sourceAssistant Park Ranger at Hunting Island State Park

Youtube

Myspace

Get Report for Matthew Robert King from Wilmington, DE, age ~48

![QLIMAX 2003 DVD - Bass D & King Matthew [HQ] QLIMAX 2003 DVD - Bass D & King Matthew [HQ]](https://i.ytimg.com/vi/_pWQRSMrPj4/0.jpg)