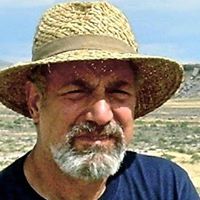

Frank J Sant

age ~60

from Eau Claire, MI

- Also known as:

-

- Francis John Sant

- Francis J Sant

- Francis Sart

- Phone and address:

-

4254 Orchard Hurst Dr, Eau Claire, MI 49111

248 318-4988

Frank Sant Phones & Addresses

- 4254 Orchard Hurst Dr, Eau Claire, MI 49111 • 248 318-4988

- 1299 Lake Jason Dr, White Lake, MI 48386 • 248 242-6807 • 248 242-6843 • 248 363-1885

- Stevensville, MI

- Livonia, MI

- Commerce Township, MI

- Southfield, MI

- Ann Arbor, MI

- Milford, MI

Work

-

Company:Falcon lakeside manufacturingJun 2011

-

Position:President

Education

-

Degree:Bachelors, Bachelor of Science

-

School / High School:University of Michigan1983 to 1988

-

Specialities:Mechanical Engineering

Skills

Automotive • Lean Manufacturing • Gd&T • Ppap • Engineering • Kaizen • Black Belt • Manufacturing Engineering • Manufacturing • Continuous Improvement • Apqp • Ts16949

Industries

Automotive

Us Patents

-

Direct Squeeze Casting

view source -

US Patent:20180029113, Feb 1, 2018

-

Filed:Jul 29, 2016

-

Appl. No.:15/223911

-

Inventors:- Detroit MI, US

Qigui Wang - Rochester Hills MI, US

Frank Sant - White Lake MI, US -

International Classification:B22D 18/02

B22C 9/06

B22D 41/04

B22C 9/24

B22D 35/04

B22D 45/00 -

Abstract:A casting system includes a pour cup, a plurality of runners that receive molten metal from the pouring cup, a top mold and a bottom mold that receive the molten metal from the plurality of runners, and a plurality of slides positioned within the top mold and the bottom mold. The positioning of the plurality of slides applies direct pressure on the molten metal in the top mold and the bottom mold to form a cast structural component.

-

Center Circular Gating Design For Squeeze Casting Induction Rotor Core

view source -

US Patent:20160175922, Jun 23, 2016

-

Filed:Dec 17, 2014

-

Appl. No.:14/573508

-

Inventors:- Detroit MI, US

QIGUI WANG - ROCHESTER HILLS MI, US

FRANK SANT - WHITE LAKE MI, US -

International Classification:B22C 9/08

B22D 17/00

H02K 15/00

B22C 9/06 -

Abstract:A number of variations may include at least one mold portion that may define a first cavity, a circular gating system, and at least one sprue. The circular gating system may surround the first cavity and define a continuous in-gate from the circular gating to the first cavity. The at least one sprue and at least one vent may be in fluid communication with the circular gating system and the first cavity.

Name / Title

Company / Classification

Phones & Addresses

Director of Engineering

EKK, INC

Computer Software Development & Consulting Services

Computer Software Development & Consulting Services

37682 Enterprise Ct, Farmington, MI 48331

Michigan

248 624-9957, 734 710-6770

Michigan

248 624-9957, 734 710-6770

Resumes

President

view sourceLocation:

White Lake, MI

Industry:

Automotive

Work:

Falcon Lakeside Manufacturing

President

Falcon Strategies

President

Ae Light Metal Casting 2006 - 2007

Director of Sales and Engineering

Grupo Bocar 1999 - 2006

General Manager

Auma Engineered Products 1999 - 2005

General Manager

President

Falcon Strategies

President

Ae Light Metal Casting 2006 - 2007

Director of Sales and Engineering

Grupo Bocar 1999 - 2006

General Manager

Auma Engineered Products 1999 - 2005

General Manager

Education:

University of Michigan 1983 - 1988

Bachelors, Bachelor of Science, Mechanical Engineering

Bachelors, Bachelor of Science, Mechanical Engineering

Skills:

Automotive

Lean Manufacturing

Gd&T

Ppap

Engineering

Kaizen

Black Belt

Manufacturing Engineering

Manufacturing

Continuous Improvement

Apqp

Ts16949

Lean Manufacturing

Gd&T

Ppap

Engineering

Kaizen

Black Belt

Manufacturing Engineering

Manufacturing

Continuous Improvement

Apqp

Ts16949

Mylife

Frank Sant Saint Louis M...

view sourceYou can find Frank Sant with our easy-to-use people finder tool. Get in touch with old friends and colleagues at MyLife.

Frank Van Sant Portsmout...

view sourceView Frank Van Sant's profile. Use our people search engine to find old friends like Frank at MyLife.

Plaxo

Frank Van Sant

view sourceIDS SCC Portsmouth RIRaytheon Past: CWO3 at US Navy

Myspace

Classmates

Frank Sant

view sourceSchools:

Country Day School St. Louis MO 1980-1984

Community:

Chris Chaney, Steve Gontram, Allan Gardner, David Weiss, Richard Metz, Jim Mauze, Jeff Ross, Kimberly Chaney, Kyle Etzkorn, Baker Baker, William Wurdack

Country Day School, St. l...

view sourceGraduates:

Edmund Whitelaw (1959-1963),

Frank Sant (1980-1984)

Frank Sant (1980-1984)

Googleplus

Frank Sant

Frank De Sant

view sourceFriends:

Isah Mounrinho Abubakar, Richard Jair Manzano Rivero, Pachii Bajda, Basem Nabil

Frank Sant'Agata

view source

Frank Sant

view source

Frank Sant

view sourceFriends:

Evan Gatch, Nicholas Clifford, Steve Hughes, David Schmid, Tony Knight

Frank Sant

view sourceFrank Sant.

Youtube

Flickr

Get Report for Frank J Sant from Eau Claire, MI, age ~60