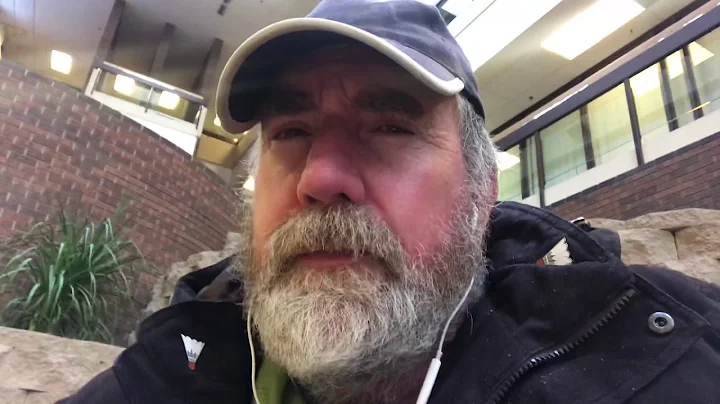

David W Mehnert

age ~78

from Lake Villa, IL

- Also known as:

-

- David E Mehnert

- David L Mehnert

- Dave L Mehnert

David Mehnert Phones & Addresses

- Lake Villa, IL

- Antioch, IL

- 25337 Cedar Crest Dr, Lake Villa, IL 60046

- 101 Oak Lane Dr, Lake Villa, IL 60046

- Glenview, IL

- Lane, IL

- 25337 W Cedar Crest Ln, Lake Villa, IL 60046

Work

-

Company:CheesebiteJul 1, 2007

-

Position:Owner

Education

-

Degree:Master of Business Administration, Masters

-

School / High School:Lake Forest Graduate School of Management1988 to 1992

-

Specialities:Management

Skills

Dairy • Manufacturing • Cheese • Ingredients • Food Industry • Supply Chain • Food Technology • Haccp • Food Manufacturing • Food Processing • Food Science • Food • Consumer Products • R&D • Product Innovation • Food Safety • Fmcg • Dairy Products • Research and Development

Industries

Dairy

Us Patents

-

Natural Biogenerated Cheese Flavoring System

view source -

US Patent:6406724, Jun 18, 2002

-

Filed:Sep 12, 2000

-

Appl. No.:09/659459

-

Inventors:Divya Shree Reddy - Lake Zurich IL

James William Moran - Antioch IL

Bashir Aideloje Elabor - Evanston IL

David Webb Mehnert - Lake Villa IL

Rudolf Johann Fritsch - Chicago IL -

Assignee:Kraft Foods Holdings, Inc. - Northfield IL

-

International Classification:A23C 912

-

US Classification:426 34, 426 35, 426 36, 426534, 426535, 426580, 426582, 426650

-

Abstract:A natural biogenerated cheese flavoring system is provided which can be used to prepare very different cheeses having desired flavor profiles. More specifically, the present cheese flavoring system contains a sulfury-cheddar flavored component, a creamy-buttery flavored component, and a cheesy flavored component. Each of these flavored components can be used as flavor building blocks with their own specific flavor profiles and/or characteristics. Using various combinations of these flavored components, cheeses having a wide variety of flavors can be produced. The flavored components are separately prepared from a highly concentrated milk substrate using compositions (e. g. , specific enzymes, cultures, and additives) and process conditions designed to provide the flavored components having specific flavor profiles and/or characteristics. The flavor concentrates can be used in process cheese, process cheese-type products, or other cheeses to produce very different cheeses with desired flavor profiles. The flavor concentrates can also be used as a natural flavoring system in other food products.

-

Shredded Cheese

view source -

US Patent:6426102, Jul 30, 2002

-

Filed:Jul 18, 2000

-

Appl. No.:09/618514

-

Inventors:Lowell Isom - St. Louis MO

David Webb Mehnert - Lake Villa IL

Nicole Grabowski - Chicago IL -

Assignee:Kraft Foods Holdings, Inc. - Northfield IL

-

International Classification:A23L 130

-

US Classification:426 72, 426 73, 426335, 426518, 426532, 426580, 426582

-

Abstract:A method of making flavorful, organoleptically pleasing, non-agglomerating, shredded natural cheese containing one or more nutritional supplements is provided. The method includes the steps of: (1) shredding a natural cheese to form pieces; (2) adding a nutritional supplement nutritional supplement comprising calcium sulfate dihydrate to the shredded cheese to form a mixture; (3) blending the mixture to achieve an essentially homogenous shredded cheese; and (4) packaging the essentially homogenous shredded cheese; wherein the calcium sulfate dihydrate is added in an amount sufficient to provide nutritionally supplementation and to provide non-agglomerating properties. The nutritional supplement of this invention allows preparation of shredded cheeses containing significantly reduced levels of conventional anti-caking agents while still maintaining the desired non-agglomerating properties. In some cases, conventional anti-caking agents are essentially eliminated.

-

Process For Mozzarella Cheese

view source -

US Patent:6475538, Nov 5, 2002

-

Filed:Jan 10, 2001

-

Appl. No.:09/759581

-

Inventors:Hiren H. Thakar - Palatine IL

David Webb Mehnert - Lake Villa IL

Wendy Munz - Naperville IL

Mohamed Saad Kettani - Schaumburg IL

William J. Zaikos - Chicago IL

Amanda Young - Dayton OH

Michael Robert Fournier - Chicago IL

Mark Gurevich - Buffalo Grove IL -

Assignee:Kraft Foods Holdings, Inc. - Northfield IL

-

International Classification:A23C 912

-

US Classification:426 43, 426 34, 426 36, 426 42, 426582

-

Abstract:The present invention is directed to an improved process of producing natural mozzarella cheese. The process starts with a liquid dairy substrate that is cultured and coagulated. The resulting curd is cut and salted. The resulting curd (i. e. , base curd) may be frozen or refrigerated and stored until needed. Once needed, the stored base curd is ground and treated in a blender where it is partially standardized to form a âpartially standardized base curd. â The partially standardized base curd is then cooked in a cooker or cooker/stretcher (preferably in a lay-down cooker) where standardization is completed by the addition of a cultured or uncultured skim milk retentate. No emulsifying salts are used in the cooker/stretcher. The cheese mass is then rapidly cooled to produce the mozzarella cheese. The conventional brine cooling step normally used in mozzarella cheese production is not used in the present invention.

-

Process For Manufacturing Cheeses And Other Dairy Products And Products Thereof

view source -

US Patent:6916496, Jul 12, 2005

-

Filed:Nov 6, 2003

-

Appl. No.:10/702718

-

Inventors:David W. Mehnert - Antioch IL, US

Rudolf J. Fritsch - Chicago IL, US

Wolfram Steffan - Ottobrunn, DE

Peter Habermeier - Scheyern, DE

Allan G. W. Bradbury - Rohrmoos, DE

Alan Wolfschoon-Pombo - Freising, DE

Mehran Rose - Hohenbrunn, DE -

Assignee:Kraft Foods R&D, Inc. - Munich

-

International Classification:A23C009/00

A23C019/00 -

US Classification:426 39, 426 36, 426582, 426583

-

Abstract:Process for manufacturing cheeses and other dairy products, and the resulting products, in which lactobionic acid is added, or generated in situ, in combination with a dairy component in the course of the process. The lactobionic acid can be used as the sole acidulent for direct acidification of the cheese, or in conjunction with reduced amounts of lactic acid culture. When the lactobionic acid is generated in situ during cheese manufacture according to the invention, a lactose oxidase is used in one embodiment to convert lactose intrinsically present in the dairy liquid ingredient(s) into lactobionic acid. The organoleptic attributes of the cheeses made using lactobionic acid as an ingredient are satisfactory and fully suitable. The process can be applied to the production of a wide variety of cheeses, including, for example, cream cheeses, hard cheeses such as cheddar, UF cheeses, process cheeses, cheddar cheeses, and so forth.

-

Method For Producing A Fermented Dairy Product

view source -

US Patent:7186427, Mar 6, 2007

-

Filed:Mar 29, 2005

-

Appl. No.:11/092352

-

Inventors:Gitte Budolfsen Lynglev - Frederiksberg, DK

Rathna Koka - Mt. Prospect IL, US

David W. Mehnert - Antioch IL, US

Rudolf J. Fritsch - Chicago IL, US -

Assignee:Novozymes A/S - Bagsvaerd

-

International Classification:A23C 9/12

-

US Classification:426 36, 426 34, 426 42, 426 43, 426580, 426582

-

Abstract:The present invention relates to a method for producing a fermented dairy product including the use of an oxidase for the conversion of lactose to lactobionic acid. Moreover, it refers to a method for affecting firmness and/or sourness of a fermented dairy product. Hereby is produced a fermented dairy product having improved functional and/or organoleptic properties.

-

Stabilization Of Fresh Mozzarella Cheese Using Fermented Whey

view source -

US Patent:7323204, Jan 29, 2008

-

Filed:Jun 25, 2004

-

Appl. No.:10/877422

-

Inventors:Zuoxing Zheng - Palatine IL, US

David Mehnert - Lake Villa IL, US

Susan Monckton - Carol Stream IL, US -

Assignee:Kraft Foods Holdings, Inc. - Northfield IL

-

International Classification:A23C 19/00

-

US Classification:426582, 426 34, 426 36, 426 41, 426532, 426654

-

Abstract:The invention is directed to a fermented and clarified nisin-containing whey and a method of making that can be used to produce a stabilized food product by adding, for example, to the pack water of fresh mozzarella cheese. The resulting stabilized food product retards or limits below detection levels the growth of toxins from pathogenic bacterial contaminants when the nisin-containing whey is added in amounts between about 10 to about 30% to the food product. The stabilized food product improves the safety of the food by retarding the growth of and improves the shelf life of the product by retarding the growth of gas forming bacteria such as bacteria from the species.

-

Process For Manufacturing Cheeses And Other Dairy Products And Products Thereof

view source -

US Patent:7329424, Feb 12, 2008

-

Filed:Jan 19, 2005

-

Appl. No.:11/038355

-

Inventors:David W. Mehnert - Antioch IL, US

Rudolf J. Fritsch - Chicago IL, US

Wolfram Steffan - Ottobrunn, DE

Peter Habermeier - Scheyern, DE

Allan G. W. Bradbury - Rohrmoos, DE

Alan Wolfschoon-Pombo - Freising, DE

Mehran Rose - Hohenbrunn, DE

Gitte Budolfsen Lynglev - Frederiksbert, DK

Hans Peter Heldt-Hansen - Virum, DK -

Assignee:Kraft Foods Holdings, Inc. - Northfield IL

-

International Classification:A23C 9/00

A23C 19/00 -

US Classification:426 39, 426 36, 426582, 426583

-

Abstract:Process for manufacturing cheeses and other dairy products, and the resulting products, in which lactobionic acid is added, or generated in situ, in combination with a dairy component in the course of the process. The lactobionic acid can be used as the sole acidulent for direct acidification of the cheese, or in conjunction with reduced amounts of lactic acid culture. When the lactobionic acid is generated in situ during cheese manufacture according to the invention, a lactose oxidase is used in one embodiment to convert lactose intrinsically present in the dairy liquid ingredient(s) into lactobionic acid. The organoleptic attributes of the cheeses made using lactobionic acid as an ingredient are satisfactory and fully suitable. The process can be applied to the production of a wide variety of cheeses, including, for example, cream cheeses, hard cheeses such as cheddar, UF cheeses, process cheeses, cheddar cheeses, and so forth.

-

Manufacture Of Large Cheese Blocks Having Reduced Moisture Variability

view source -

US Patent:7560129, Jul 14, 2009

-

Filed:Mar 23, 2005

-

Appl. No.:11/087981

-

Inventors:David Webb Mehnert - Lake Villa IL, US

Divva Shree Reddy - Lake Zurich IL, US

Carie Lynn Wolters - Round Lake IL, US -

Assignee:Kraft Foods Global Brands LLC - Northfield IL

-

International Classification:A23C 19/00

-

US Classification:426582, 426491, 426512, 426580

-

Abstract:The present invention is directed to a process for making a block of cheese having reduced moisture variability. A bulk container having a bottom and sidewalls, and a tube having a fill end and an opposite discharge end, are provided. The discharge end of the tube is positioned at an approximately central axial location of the container. Cheese curd is introduced into the container, and the tube via its fill end. Then, a chilled brine is introduced into the tube via its fill end to mix with curd therein. Preferably, the chilled brine has a salt content which approximately matches the salt content of the moisture phase of the cheese curd. The tube is removed from the cheese curd in the container. The cheese curd is pressed into a curd mass, and then cooled, and thereafter cured, providing a cheese block having reduced moisture variability.

Resumes

Owner

view sourceLocation:

Chicago, IL

Industry:

Dairy

Work:

Cheesebite

Owner

Cheesebite

Manageing Director

Mondelēz International Jul 1981 - Jun 2007

Kraft Foods Fellow

Chicago Section Ift 2000 - 2005

Treasurer

Owner

Cheesebite

Manageing Director

Mondelēz International Jul 1981 - Jun 2007

Kraft Foods Fellow

Chicago Section Ift 2000 - 2005

Treasurer

Education:

Lake Forest Graduate School of Management 1988 - 1992

Master of Business Administration, Masters, Management Southern Illinois University, Carbondale 1972 - 1979

Masters, Master of Arts, Bachelors, Bachelor of Arts, Microbiology Champaign Senior High School

Champaign High School

Master of Business Administration, Masters, Management Southern Illinois University, Carbondale 1972 - 1979

Masters, Master of Arts, Bachelors, Bachelor of Arts, Microbiology Champaign Senior High School

Champaign High School

Skills:

Dairy

Manufacturing

Cheese

Ingredients

Food Industry

Supply Chain

Food Technology

Haccp

Food Manufacturing

Food Processing

Food Science

Food

Consumer Products

R&D

Product Innovation

Food Safety

Fmcg

Dairy Products

Research and Development

Manufacturing

Cheese

Ingredients

Food Industry

Supply Chain

Food Technology

Haccp

Food Manufacturing

Food Processing

Food Science

Food

Consumer Products

R&D

Product Innovation

Food Safety

Fmcg

Dairy Products

Research and Development

Youtube

Googleplus

David Mehnert

David Mehnert

David B. Mehnert Jr. Pho...

view sourceFriends:

Meghan Sanchez, Dave Quadrato, Ben Munger, Andrew McArdle

David B. Mehnert Jr. (Phoenix, AZ)

David W. Mehnert

view sourceGet Report for David W Mehnert from Lake Villa, IL, age ~78