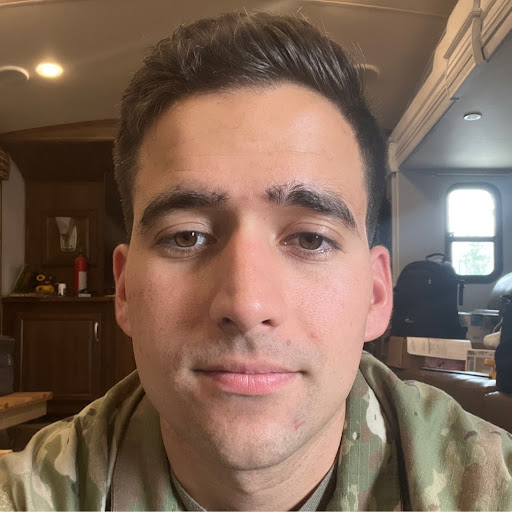

Charles K Hager

age ~43

from Long Grove, IA

- Also known as:

-

- Charles Kendel Hager

- Charles T Hager

Charles Hager Phones & Addresses

- Long Grove, IA

- Eldridge, IA

- 4606 Kelling St, Davenport, IA 52806 • 563 386-1525

- Danville, IL

- Dubuque, IA

- Windermere, FL

- 1799 S 9Th Ave, Eldridge, IA 52748 • 563 582-2591

Work

-

Position:Executive, Administrative, and Managerial Occupations

Education

-

Degree:High school graduate or higher

Resumes

Pilot

view sourceLocation:

454 North Ave, Aurora, IL 60505

Industry:

Airlines/Aviation

Work:

Chartaire Apr 2005 - Apr 2011

Chief Pilot

John Deere Apr 2005 - Apr 2011

Pilot

Blue Sky Aero Inc Apr 2003 - Apr 2005

Certified Flight Instructor

Chief Pilot

John Deere Apr 2005 - Apr 2011

Pilot

Blue Sky Aero Inc Apr 2003 - Apr 2005

Certified Flight Instructor

Education:

Embry - Riddle Aeronautical University 2012 - 2015

Master of Business Administration, Masters, Aviation Lewis University 2000 - 2003

Bachelors, Bachelor of Science, Aviation

Master of Business Administration, Masters, Aviation Lewis University 2000 - 2003

Bachelors, Bachelor of Science, Aviation

Interests:

Motorcycling

Electronics

Outdoors

Shooting

Sports

Electronics

Outdoors

Shooting

Sports

Languages:

English

Charles Hager

view source

Charles Hager

view source

Charles Hager

view source

Charles Hager

view source

Charles Hager

view source

Charles Alan Hager

view source

Charles Hager

view sourceLawyers & Attorneys

Charles Hager - Lawyer

view sourceISLN:

906786350

Admitted:

1982

University:

Rutgers University at New Brunswick, B.A., 1979

Law School:

Cornell University, J.D., 1982

License Records

Charles Kendel Hager

Address:

1799 S 9 Ave, Eldridge, IA 52748

License #:

A4201032

Category:

Airmen

Charles E Hager

Phone:

954 298-0423

License #:

62801 - Expired

Category:

Health Care

Expiration Date:

Dec 1, 1994

Type:

Emergency Medical Technician

Vehicle Records

-

Charles Hager

view source -

Address:1799 S 9 Ave, Eldridge, IA 52748

-

VIN:5GAKVBED3BJ390172

-

Make:BUICK

-

Model:ENCLAVE

-

Year:2011

Us Patents

-

Linear Gas Valve Cycle Control, Shut-Off-Valve And Self Test

view source -

US Patent:6409807, Jun 25, 2002

-

Filed:May 23, 2000

-

Appl. No.:09/576050

-

Inventors:Charles Bradley Hager - Davenport IA

Kevin Michael Dailey - Rock Island IL -

Assignee:Litton Systems, Inc. - Los Angeles CA

-

International Classification:B01D 5304

-

US Classification:96111, 96114, 96130

-

Abstract:The present invention relates to detecting the state of a slide block positioned in a linear valve and using the position of the slide block to predict the health of a linear valve and provide information to a controller/monitor. An operator is provided with information before failure occurrence to allow preventative maintenance of the linear valve. The linear valve is constructed with two canister ports and a vent port. The slide block can be constructed to block the two canister ports and vent port simultaneously. The system can control the position of the block, when provided with position information, hence, using the slide block as a shutoff valve. The typical slide valve can be used as an integral slide shutoff valve, reducing system complexity and reducing system weight, which is critical to airborne applications.

-

Variable Inlet Air Restriction For Composition Control Of Product Gas

view source -

US Patent:6669758, Dec 30, 2003

-

Filed:Jun 27, 2002

-

Appl. No.:10/064268

-

Inventors:Russell F. Hart - Blue Grass IA

Charles B. Hager - Davenport IA -

Assignee:Carleton Life Support Systems, Inc. - Orchard Park NY

-

International Classification:B01D 53047

-

US Classification:95 8, 95 13, 95 96, 96111, 96116, 96130, 96399

-

Abstract:A controller system for a molecular sieve device controls a product gas generated by n molecular sieve beds for separating a gas from an input gas supply. A valve assembly with n states has an input receiving the input gas and n outlets. Each valve state in a first position creates an open passageway from the input of the slide valve to an outlet. Transitioning a valve from the first to a second position creates a variable amount of restriction in the flow of gas between the input and a selected outlet.

-

Air Conserving Slide Valve

view source -

US Patent:7036521, May 2, 2006

-

Filed:Jun 17, 2003

-

Appl. No.:10/250243

-

Inventors:Charles B. Hager - Davenport IA, US

-

Assignee:Carleton Life Support Systems, Inc. - Orchard Park NY

-

International Classification:F16K 11/06

-

US Classification:137309, 96130, 13762543

-

Abstract:A slide type valve (V) for regulating a gas generating system () that has at least a first and a second gas concentrating bed unit () includes an outer body () with a slide face () having at least three open ports () communicating with an interior cavity () formed in the outer body (). A vent port () and at least two bed ports () are adapted to communicate an air flow with a gas concentrating bed unit (). The vent port () is formed between two bed ports. A slide block () having an essentially flat face () slides along the slide face interior surface () of the outer body () and has an interior cavity () and a first and a second opening (). The slide block slide face () has a closing portion () positioned between the first and second openings (). A controller (C) moves the slide block () between a first state (S) and a second state (S) for desired air flow.

-

Oxygen Concentrator With Beds' Duty Cycle Control And Self-Test

view source -

US Patent:58580638, Jan 12, 1999

-

Filed:Jun 3, 1997

-

Appl. No.:8/868419

-

Inventors:Tuan Quoc Cao - Davenport IA

Russell Frank Hart - Blue Grass IA

William David Molis - Davenport IA

Richard Kent Frantz - Davenport IA

Charles Bradley Hager - Davenport IA

Victor Paul Crome - Davenport IA -

Assignee:Litton Systems, Inc. - Davenport IA

-

International Classification:B01D 53047

-

US Classification:95 11

-

Abstract:A method of controlling an oxygen concentrator having a first sieve bed operated over successive control periods according to a duty cycle for alternately pressurizing and flushing the first sieve bed and a second sieve bed operated over the successive control periods according to a reciprocal of the duty cycle is disclosed. The duty cycle and the reciprocal duty cycle are adjusted during every second one of the successive control periods to change the pressurizing relative to the flushing of the first sieve bed and to change the flushing relative to the pressurizing of the second sieve bed, for reducing concentration of oxygen produced. The duty cycle and the reciprocal duty cycle are adjusted during remaining control periods to change the flushing relative to the pressurizing of the first sieve bed and to change the pressurizing relative to the flushing of the second sieve bed, such that water vapor is purged from the first and second sieve beds after pressurizing thereof. A pressure-swing adsorption (PSA) subsystem performance check is disclosed. This test is performed as part of a maintenance BIT (Built-In-Test) function.

Classmates

Charles Hager

view sourceSchools:

Alexander Hamilton Humanities Magnet Los Angeles CA 1971-1975

Community:

William Cavette

Charles Hager

view sourceSchools:

Vestavia Hills Primary School East Vestavia Hills AL 1982-1983, Vestavia Hills Primary School West Vestavia Hills AL 1984-1985, Louis Pizitz Middle School Vestavia Hills AL 1986-1988

Community:

Scott Walker, Christie Henry, Going Green

Charles Hager

view sourceSchools:

Meadow Creek Christian High School Andover MN 2001-2002

Community:

Donald Weber

Vestavia Hills Primary Sc...

view sourceGraduates:

Charles Hager (1980-1981),

Kellyann Ernst (1978-1982),

Adam Neighbors (1985-1989)

Kellyann Ernst (1978-1982),

Adam Neighbors (1985-1989)

Flickr

Googleplus

Charles Hager

Work:

ICS Inc. - Systems Engineer

Charles Hager

Charles Hager

Charles Hager

Charles Hager

Charles Hager

Charles Hager

Charles Hager

Plaxo

CHARLES HAGER

view sourceSuperior Court of New Jersey

Myspace

Charles Hager

view source

Charles Hager Sr

view source

Charles Hager

view source

Charles Hager

view source

Charles Hager

view source

Charles Hager

view source

Charles Hager Jr.

view source

Andrew Charles Hager

view sourceYoutube

Get Report for Charles K Hager from Long Grove, IA, age ~43