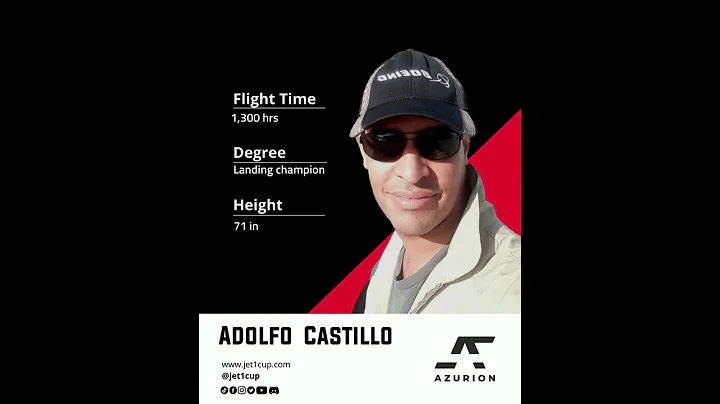

Adolfo Nicholas Castillo

age ~47

from North Miami, FL

- Also known as:

-

- Adolfo Nicolas Castillo

- Adolfo N Castillo

- Adolfo N Lora

- Nicolas A Castillo

- Adolfo Cristillo

- Adolf Castillo

- Adolfo Costillo

Adolfo Castillo Phones & Addresses

- North Miami, FL

- Hialeah, FL

- Miramar, FL

- Myrtle Beach, SC

Work

-

Company:Adolfo Del Castillo, P.A.

-

Address:7530 Sw 163Rd St, Palmetto Bay, FL 33157

-

Specialities:Litigation - 34% • Insurance - 11% • Health Care - 11% • Family - 11% • Personal Injury - 11% • Government - 11% • Unknown - 11%

Education

-

Degree:JD - Juris Doctor

-

School / High School:University of Miami School of Law

Ranks

-

Licence:Florida - Member in Good Standing

-

Date:1963

Specialities

REO / Bank Owned • Short sales • Residential sales • Luxury homes • First time home buyers • Distressed properties • Horse properties • Probate • Staging • Relocation

Name / Title

Company / Classification

Phones & Addresses

President

ADOLFO J CASTILLO PA

Business Services at Non-Commercial Site · Nonclassifiable Establishments

Business Services at Non-Commercial Site · Nonclassifiable Establishments

10928 SW 112 Ave, Miami, FL 33176

President

DOCTOR DOLPHIN DRIVEWAY PAINTING INC

13301 SW 2 St, Miami, FL 33184

Principal

Fito Mobile Carwash

Carwash · Nonclassifiable Establishments

Carwash · Nonclassifiable Establishments

15501 NE 6 Ave, Miami, FL 33162

Director

Royal Electrical Supply, Inc.

Electrical/Electronic Manufacturing · Ret Hardware Whol Electrical Equip Mfg Elec Indstl Equip · Whol Electrical Equip Ret Hardware · Home Improvement Stores · Other Building Material Dealers

Electrical/Electronic Manufacturing · Ret Hardware Whol Electrical Equip Mfg Elec Indstl Equip · Whol Electrical Equip Ret Hardware · Home Improvement Stores · Other Building Material Dealers

3680 NW 54 St, Miami, FL 33142

305 634-4600, 305 635-2877

305 634-4600, 305 635-2877

President

Dolphin Driveway Painting Plus Inc

2831 NW 6 St, Miami, FL 33125

Owner, President

Adolfo Del Castillo

Legal Services Office

Legal Services Office

420 S Dixie Hwy, Miami, FL 33146

305 667-4949

305 667-4949

Director

Data Link Business Machines, Inc

3400 Coral Way, Miami, FL 33145

Director

Legal Assistant Services, Inc

119 Gables Ctr, Miami, FL 33134

Lawyers & Attorneys

Adolfo Del Castillo, Palmetto Bay FL - Lawyer

view sourceAddress:

Adolfo Del Castillo, P.A.

7530 Sw 163Rd St, Palmetto Bay, FL 33157

7530 Sw 163Rd St, Palmetto Bay, FL 33157

Licenses:

Florida - Member in Good Standing 1963

Education:

University of Miami School of Law

Degree - JD - Juris Doctor - Law

Degree - JD - Juris Doctor - Law

Specialties:

Litigation - 34%

Insurance - 11%

Health Care - 11%

Family - 11%

Personal Injury - 11%

Government - 11%

Unknown - 11%

Insurance - 11%

Health Care - 11%

Family - 11%

Personal Injury - 11%

Government - 11%

Unknown - 11%

License Records

Adolfo J Castillo

Address:

10928 SW 112 Ave, Miami, FL 33176

License #:

SL3261117 - Active

Category:

Real Estate

Issued Date:

Jul 20, 2012

Effective Date:

Apr 13, 2016

Expiration Date:

Mar 31, 2018

Type:

Sales Associate

Adolfo X Castillo

Address:

14262 SW 146 Ave, Miami, FL

Phone:

954 600-8603

License #:

40290 - Active

Category:

Health Care

Issued Date:

Jan 2, 2007

Effective Date:

Aug 14, 2012

Expiration Date:

Aug 31, 2018

Type:

Clinical Laboratory Personnel

Real Estate Brokers

Adolfo Castillo, Sylmar Los Angeles Agent

view sourceSpecialties:

REO / Bank Owned

Short sales

Residential sales

Luxury homes

First time home buyers

Distressed properties

Horse properties

Probate

Staging

Relocation

Short sales

Residential sales

Luxury homes

First time home buyers

Distressed properties

Horse properties

Probate

Staging

Relocation

Work:

Pinnacle Estate Properties, Inc.

818 482-0327 (Phone)

License #01275303

818 482-0327 (Phone)

License #01275303

Client type:

Home Buyers

Home Sellers

Home Sellers

Property type:

Single Family Home

Condo/Townhome

Multi-family

Condo/Townhome

Multi-family

Resumes

Security Officer

view sourceLocation:

Miami Beach, FL

Industry:

Hospitality

Work:

Faena Hotel

Security Officer

Security Officer

Medical Laboratory Scientist

view sourceLocation:

Fort Lauderdale, FL

Industry:

Hospital & Health Care

Work:

Holy Cross Hospital

Medical Technologist

Broward Health North 2013 - 2014

Senior Medical Technologist

Boca Raton Regional Hospital 2013 - 2014

Med Technician

Aureus Medical Group 2013 - 2014

Medical Laboratory Scientist

Medical Technologist

Broward Health North 2013 - 2014

Senior Medical Technologist

Boca Raton Regional Hospital 2013 - 2014

Med Technician

Aureus Medical Group 2013 - 2014

Medical Laboratory Scientist

Education:

Atlantic Institute of Oriental Medicine 2016 - 2019

Masters, Chinese, Medicine Inter American University School of Law 2003 - 2004

University of Puerto Rico - Cayey

Masters, Chinese, Medicine Inter American University School of Law 2003 - 2004

University of Puerto Rico - Cayey

Skills:

Laboratory Medicine

Clinical Research

Cerner

Medical Technology

Phlebotomy

Emr

Medicine

Electronic Medical Record

Hematology

Laboratory

Clinical Research

Cerner

Medical Technology

Phlebotomy

Emr

Medicine

Electronic Medical Record

Hematology

Laboratory

Adolfo Del Castillo

view source

Adolfo Del Castillo

view source

Adolfo Martin Romero Castillo

view source

Adolfo Castillo

view source

Adolfo Castillo

view sourceLocation:

United States

Us Patents

-

Method Of Joining Wooden Members

view source -

US Patent:40472825, Sep 13, 1977

-

Filed:Apr 19, 1976

-

Appl. No.:5/678393

-

Inventors:John Calvin Jureit - Coral Gables FL

Adolfo Castillo - Miami FL

Roy Leutwyler - Miami FL

Larry Brodsky - Sunrise FL

Ben Kushner - Miami FL -

Assignee:Automated Building Components, Inc. - Miami FL

-

International Classification:B23P 1100

-

US Classification:29432

-

Abstract:The apparatus includes a conveyor table having pairs of press heads mounted on its opposite sides. Strips of sheet metal stock from coils are fed through respective die sets for punching integrally extending teeth in the metal strips and the connector plate stock thus formed is fed into the respective paths of movement of upper and lower press platens. The platens are movable toward one another to substantially simultaneously cut the connector stock to predetermined lengths to form connector plates and embed the teeth of the connector plates on opposite sides of joints formed by wooden frame members disposed on the conveyor between the press heads. Simultaneously with the pressing operation, the die set punches additional teeth into the strip. Upon completion of the pressing operation, a feed mechanism locates predetermined lengths of connector stock with struck teeth between the press platens for the next cut and embedment operation. Selectively extensible and retractable stops are provided on the conveyor table and press heads against which respective webs and chords of a frame undergoing fabrication are butted to locate the same in position forming a completed frame.

-

Press

view source -

US Patent:41049624, Aug 8, 1978

-

Filed:Mar 14, 1977

-

Appl. No.:5/777090

-

Inventors:Adolfo Castillo - Miami FL

-

Assignee:Automabed Building Components, Inc. - Miami FL

-

International Classification:B30B 132

-

US Classification:100100

-

Abstract:A press which is suitable for use in fabricating wooden trusses is disclosed, wherein the press includes a lower stationery press platen and an upper moveable press platen opposing the lower press platen. Bellcranks are mounted on the lower press platen supporting structure on opposite sides of the press. A transfer bar interconnects the upper ends of the bellcranks. A hydraulic cylinder connects the moveable, upper press platen and a bellcrank. Guide rods are provided to guide the moveable upper press platen during vertical movement above the lower press platen. The press exerts substantial pressures upon the trusses or the like being pressed between the platens, while maintaining the platens in a generally parallel relationship, in spite of uneven press loading.

-

Flat Chord Truss Jig Assembly

view source -

US Patent:40440931, Aug 23, 1977

-

Filed:Sep 26, 1974

-

Appl. No.:5/509568

-

Inventors:John Calvin Jureit - Coral Gables FL

Adolfo Castillo - Miami FL -

Assignee:Automated Building Components, Inc. - Miami FL

-

International Classification:B23Q 300

-

US Classification:269321F

-

Abstract:The flat chord truss jig assembly includes a jig pad carrying two pairs of laterally spaced elongated guide bars. Releasable clamps are provided along the opposite outer edges of the pad and engageable with the outermost pair of bars. The innermost pair of bars are connected by longitudinally spaced rods reverse threaded at opposite ends for threaded engagement with the bars whereby rotation of the rods moves the innermost pair of bars toward and away from one another to introduce similar camber in each innermost bar. An end locator plate is positioned between each pair of bars at opposite ends of the truss. The chords and diagonals of a flat chord truss are disposed between the pairs of bars on opposite sides of the jig pad and connector plates of the type having integrally struck teeth are prepositioned at the joints between such chords and diagonals. The jig assembly is moved through a press whereupon the teeth of the connector plates are embedded into the joints to complete a flat chord truss.

-

Automatic Frame Machine

view source -

US Patent:39852784, Oct 12, 1976

-

Filed:Apr 7, 1975

-

Appl. No.:5/565756

-

Inventors:John Calvin Jureit - Coral Gables FL

Adolfo Castillo - Miami FL

Roy Leutwyler - Miami FL

Larry Brodsky - Sunrise FL

Ben Kushner - Miami FL -

Assignee:Automated Building Components, Inc. - Miami FL

-

International Classification:B27F 702

-

US Classification:227 86

-

Abstract:The apparatus includes a conveyor table having pairs of press heads mounted on its opposite sides. Strips of sheet metal stock from coils are fed through respective die sets for punching integrally extending teeth in the metal strips and the connector plate stock thus formed is fed into the respective paths of movement of upper and lower press platens. The platens are movable toward one another to substantially simultaneously cut the connector stock to predetermined lengths to form connector plates and embed the teeth of the connector plates on opposite sides of joints formed by wooden frame members disposed on the conveyor between the press heads. Simultaneously with the pressing operation, the die set punches additional teeth into the strip. Upon completion of the pressing operation, a feed mechanism locates predetermined lengths of connector stock with struck teeth between the press platens for the next cut and embedment operation. Selectively extensible and retractable stops are provided on the conveyor table and press heads against which respective webs and chords of a frame undergoing fabrication are butted to locate the same in position forming a completed frame.

-

Apparatus And Methods Of Fabricating Wooden Frames, Panels And The Like

view source -

US Patent:40316041, Jun 28, 1977

-

Filed:Dec 12, 1975

-

Appl. No.:5/640323

-

Inventors:John Calvin Jureit - Coral Gables FL

Howell J. Cotten - Keswick VA

Adolfo Castillo - Miami FL

Roy Leutwyler - Miami FL -

Assignee:Automated Building Components, Inc. - Miami FL

-

International Classification:B27F 700

B27F 702 -

US Classification:29429

-

Abstract:The apparatus includes a pair of spaced conveyors for conveying upper and lower frame plates through a pair of nailing assemblies. Each nailing assembly includes a nailing gun pivotal between upper and lower positions whereby nails can be driven through the plate and into a stud disposed between the plates at positions spaced along the width of the plate. The conveyor includes a drive unit for advancing the plates through the nailing assemblies discrete distances of 1. 5, 16 or 24 inches. One of the conveyors and nailing assemblies is movable laterally relative to the other conveyor and nailing assembly whereby adjustments in width of the frame undergoing fabrication is accomplished. In use, a stud is butted against retractable stops upstanding between the nailing assemblies. Upon command, clamps carried by the nailing assemblies clamp the stud and frame plates one to the other and the nailing gun automatically drives a nail through the plate into the stud.

-

Building Truss Fabrication Apparatus

view source -

US Patent:46691847, Jun 2, 1987

-

Filed:Oct 29, 1984

-

Appl. No.:6/665958

-

Inventors:Adolfo Castillo - Miami FL

-

Assignee:Gang-Nail Systems - Miami FL

-

International Classification:B23P 1900

-

US Classification:29798

-

Abstract:A building truss fabrication apparatus in which a plurality of press head assemblies are supported by an overhead gantry support so that the various press assemblies are movable in an x-y coordinate space. A movable jig table is arranged to move between an assembly position and a pressing position within the apparatus. The movement of the jig table is hydraulically powered as are the press head assemblies. The entire apparatus is operable by a single hydraulic power source. A standard air compressor is used to generate air pressure of pneumatic clamps used on the jig table. The pneumatic clamps are part of the jig fixtures which hold lumber components into a truss preformed shape. Connector plates or nail plates are pressed into the component ends by the press head assemblies in order to complete fabrication of the building truss.

-

Methods For Fabricating Wooden Frames And The Like

view source -

US Patent:39395480, Feb 24, 1976

-

Filed:Apr 19, 1974

-

Appl. No.:5/462443

-

Inventors:John Calvin Jureit - Coral Gables FL

Roy Leutwyler - Miami FL

Larry Brodsky - Miami FL

Benjamin Kushner - Miami FL

Adolfo Castillo - Miami FL -

Assignee:Automated Building Components, Inc. - Miami FL

-

International Classification:B23P 1100

-

US Classification:29432

-

Abstract:The apparatus includes a conveyor table having press heads mounted on opposite sides. Coils of connector plate stock having prepunched integrally extending teeth feed upper and lower press platens movable toward one another to substantially simultaneously cut the connector stock to predetermined lengths to form connector plates and embed the teeth of the connector plates on opposite sides of joints formed by wooden frame members disposed on the conveyor between the press heads. Upon completion of the pressing operation, a feed mechanism locates predetermined lengths of connector stock between the press platens for the next cut and embedment operation. Selectively extensible and retractable stops are provided on the conveyor table and press heads against which respective webs and chords of the frame being fabricated are butted to locate the same in position forming a completed frame. Clamps on the conveyor press the chords against the web ends while the connector plates are embedded in the joints.

-

Methods For Forming Wooden Joints

view source -

US Patent:40818934, Apr 4, 1978

-

Filed:Aug 4, 1976

-

Appl. No.:5/711499

-

Inventors:John Calvin Jureit - Coral Gables FL

Roy Leutwyler - Miami FL

Larry Brodsky - Sunrise FL

Benjamin Kushner - Miami FL

Andrew G. Seipos - Miami FL

Adolfo Castillo - Miami FL -

Assignee:Automated Building Components, Inc. - Miami FL

-

International Classification:B23P 1100

-

US Classification:29432

-

Abstract:The method includes the use of a conveyor table mounting press assemblies above and below the table respectively. Coils of connector plate stock having prepunched integrally extending teeth feed upper and lower press platens of the press assemblies, the platens being movable toward one another to substantially simultaneously cut the connector stock to predetermined lengths to form connector plates and embed the teeth of the connector plates on opposite sides of a joint formed by a pair of wooden frame members disposed in end-to-end butting relation on the conveyor between the press assemblies. To join a pair of wooden members end to end in butting relation, the members are displaced forwardly along the conveyor table with the trailing member offset laterally from the leading member until the offset member butts a stop which locates the butt joint in accurate registration between the press platens. Clamp cylinders displace both members against a fence to longitudinally align the members. The press platens thereafter move to cut discrete plates from the coils and embed the teeth thereof into the opposite sides of the joint.

Myspace

Adolfo Castillo

view source

Adolfo A Castillo

view source

Adolfo Monica Castillo

view source

Gustavo Adolfo Castillo

view source

Adolfo Isquitepeaved Cast...

view source

Adolfo Castillo Jimenez

view source

Adolfo Castillo

view source

Adolfo Castillo

view sourceClassmates

Adolfo Castillo

view sourceSchools:

Louisiana State Universidy Baton Rouge LA 1986-1990

Community:

Mohd Omar, Mohamed Ismail

Adolfo Castillo

view sourceSchools:

Taft High School Taft TX 1993-1997

Texas A&M University,...

view sourceGraduates:

Adolfo Castillo (2000-2004),

Terri McNeil (1982-1983),

John Ramirez (2004-2009),

Mack Donald (2000-2004)

Terri McNeil (1982-1983),

John Ramirez (2004-2009),

Mack Donald (2000-2004)

Louisiana State Universit...

view sourceGraduates:

Adolfo Castillo (1979-1984),

Victoria Prilipko (1990-1994),

Erica James (2008-2012)

Victoria Prilipko (1990-1994),

Erica James (2008-2012)

Plaxo

ADOLFO CASTILLO U.

view sourcePast: SURELECTRIC, C.A. at Sur Americana de Electricidad, c.a.

Googleplus

Adolfo Castillo

Work:

International Artist Publishing, Inc. - Production Manager

Education:

Collin College - Visual Communications

Adolfo Castillo

Education:

Universidad de San Carlos de Guatemala - Derecho

Tagline:

Lucha por lo que amas!

Adolfo Castillo

Education:

CECYT

Adolfo Castillo

Adolfo Castillo

Adolfo Castillo

Adolfo Castillo

Tagline:

Car rien n'est gratuit dans la vie.!!

Adolfo Castillo

Youtube

Get Report for Adolfo Nicholas Castillo from North Miami, FL, age ~47